Videos

Courses & Workshops

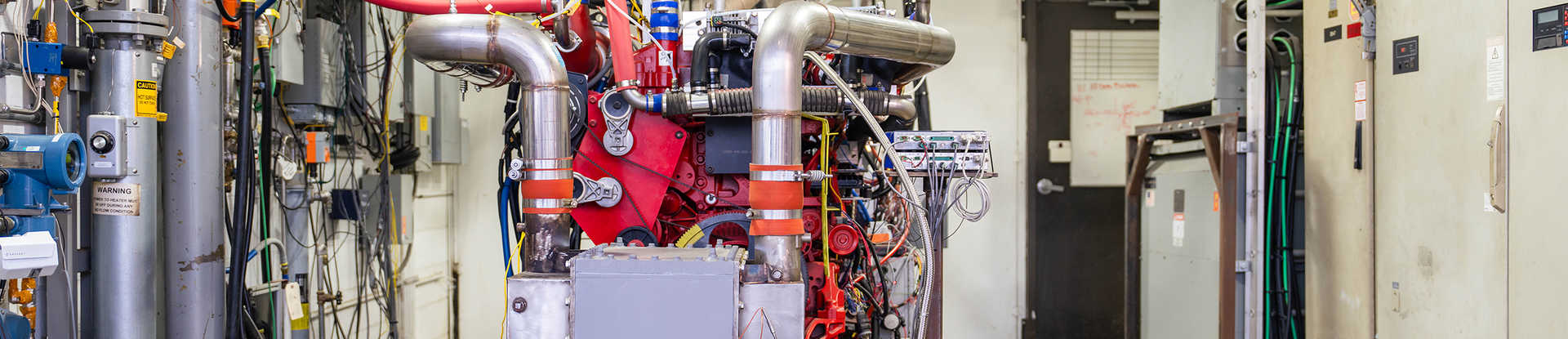

SwRI is hosting a Pulsations & Vibrations: Analysis and Testing Training Course. This course offers hands-on applications... MORE

Join us for a free webinar hosted by Michael Marshall and Ellen Smith.

Join us for a free webinar hosted by Aaron Rimpel.

Join us for a free webinar hosted by Emilio Gordon.

SwRI is hosting a Turbomachinery Design week-long training course.

Texas Manufacturing Assistance Center (TMAC), a program of SwRI, is partnering with SAMA to host a Lean Manufacturing... MORE

SwRI is hosting Introduction to Propulsion Simulation Using NPSS courses.